Fly ash bricks have emerged as a sustainable and eco-friendly alternative to traditional clay bricks, gaining traction worldwide. In India, the government has introduced various policies and regulations to encourage the adoption of fly ash bricks and ensure compliance with environmental standards. Here’s a closer look at these policies and how they impact the operations of fly ash brick plants.

Key Government Policies Promoting Fly Ash Bricks

Mandatory Utilization of Fly Ash:

The government mandates that power plants and other industries producing fly ash supply it free of cost or at a nominal price to brick manufacturers within a specified radius. This ensures a steady and affordable supply of raw materials.Incentives for Eco-Friendly Products:

Several state governments offer subsidies, tax exemptions, and incentives to promote eco-friendly building materials, including fly ash bricks.Environmental Guidelines:

Fly ash brick plants must comply with environmental regulations, including proper disposal of waste and maintaining emission standards. Non-compliance can result in penalties.Construction Norms:

Many government construction projects now prioritize the use of fly ash bricks to reduce the environmental impact of traditional clay bricks.Training and Awareness Programs:

The government and industry bodies frequently organize workshops to educate manufacturers about advanced technologies, quality standards, and sustainability practices.

Challenges in Adhering to Regulations

While these policies are beneficial, implementing them can be challenging due to logistical hurdles, inconsistent supply of fly ash, and limited awareness among manufacturers. However, organizations like Rajratan Industries are committed to supporting fly ash brick manufacturers with high-quality PAC Pallets, ensuring their operations are efficient and compliant with government standards.

Need PAC Pallet Samples for Your Fly Ash Brick Plant?

Call us at +91 9685927927 (Monday to Saturday, 10 AM to 6 PM) for a free sample and experience the quality that enhances your production efficiency

PAVER BOARD FOR MOULD STACKING

PAC® Pallet For Mould Stacking

PAC® paver boards keep your paver blocks neatly stacked during production. Their rigid design ensures molds stay stable, giving your pavers a smooth finish and perfect shape every time.

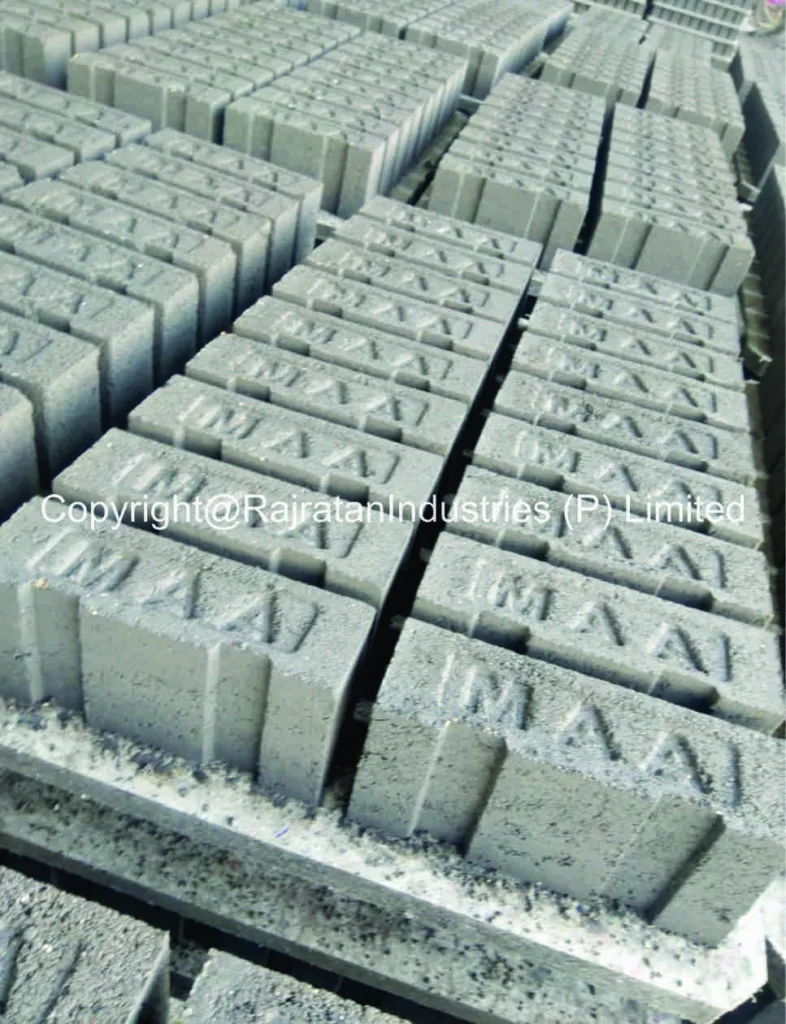

FLY ASH BRICK PALLET

PAC® Brick Pallet

A strong Fly Ash Brick Pallet is key to making sturdy bricks. PAC® pallets handle heavy hydraulic pressure, ensuring your bricks have high strength and a clean look.

FLYASH/CEMENT BLOCK PALLETS

PAC® Cement Block Pallet

For cement blocks (like solid or anchor blocks), PAC® pallets are built tough. They work perfectly with vibration machines, giving your blocks the right density and shape.