Pallet boards may look like simple accessories on a construction site, but in India’s brick, block, and paver manufacturing industry, they play a far more significant role. The stability, durability, and dimensional accuracy of a pallet directly influence block quality, machine efficiency, and long-term operating costs.

However, the Indian market is crowded with different pallet options – wooden pallets, PVC sheets, recycled municipal plastic boards, and engineered composite pallets like Rajratan’s PAC® Pallet. Understanding how each is manufactured is essential for making an informed choice.

This feature breaks down the manufacturing behind each type – and why engineering, not appearance, determines performance.

1. Wooden Pallets: Traditional but Technically Limited

How They’re Made

Wooden pallets are manufactured by:

- Layering softwood or low-density hardwood

- Bonding them with resin

- Pressing under heat

- Applying moisture-resistant coatings

Where Manufacturing Fails

Wood is a natural, inconsistent material. Even when processed properly, it still:

- Absorbs water

- Warps under load

- Swells during monsoon

- Cracks under vibration

- Loses shape as the coating wears off

For India’s humid climate and high-vibration block plants, the manufacturing limitations of wood become very visible within months.

2. PVC Pallets: Smooth Surface, Weak Core

How They’re Made

PVC boards are extruded from polyvinyl chloride mixed with stabilizers and fillers, then laminated for surface finish.

Where Manufacturing Fails

PVC is a thermoplastic — it softens in heat.

This means in many Indian plants:

- Boards warp under sun exposure

- The lamination film peels

- Load-bearing capacity drops

- Edges deform during curing

PVC looks polished when new, but the manufacturing process limits its use for heavy-duty block or paver applications.

3. Recycled Municipal Plastic Boards: Cheap but Unstable

How They’re Made

These boards use municipal waste plastic — mixed polymers, paper fibres, moisture, and contaminants.

They are made by:

- Washing mixed waste

- Shredding

- Melting into sheets

- Applying a thin surface coating

Manufacturing Challenges

Because the feedstock is inconsistent, these boards often:

- Become brittle internally

- Carry moisture and impurities

- Crack during vibration

- Warp under heat

- Swell as paper fibres inside absorb water

Their manufacturing makes them cheap — but mechanically unreliable for any serious production setup.

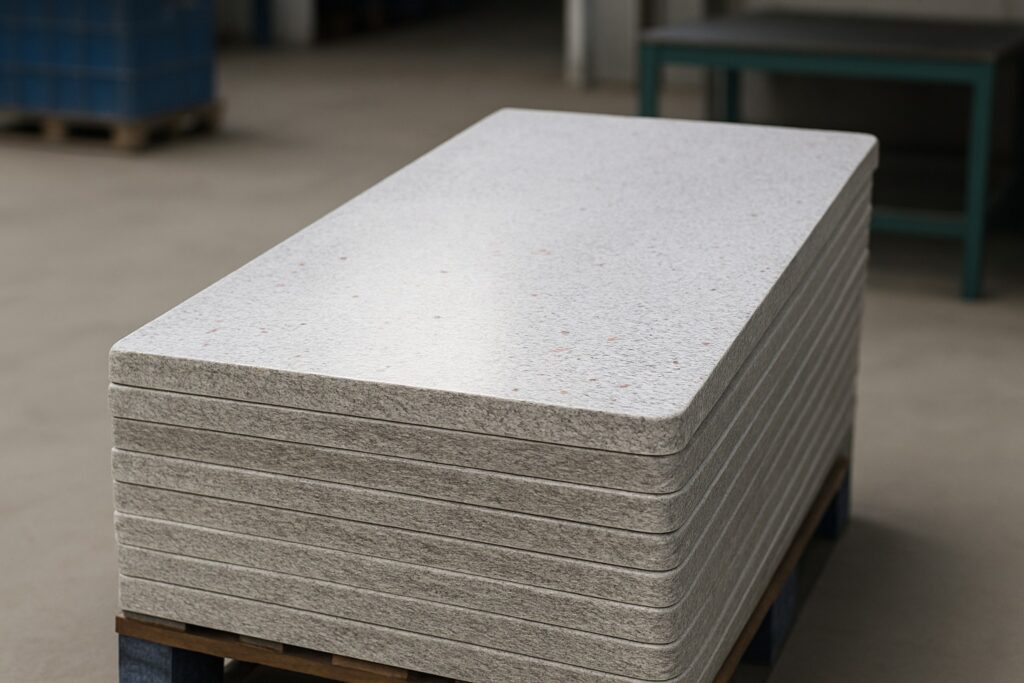

4. Rajratan’s PAC® Pallet Boards

How They’re Made

High-quality composite boards are engineered using:

- Industrial-grade pre-consumer plastics (PP, LDPE, HDPE)

- Aluminium Oxide

- Fibres

- XLP metals

- (For heavy-duty variants) Steel tube frames

Unlike municipal plastic, these raw materials are pure, uniform, and mechanically strong resulting in a board designed specifically for production environments.

Rajratan’s PAC® Pallets are individually moulded and calibrated, not cut from sheets.

This ensures:

- Perfect flatness

- Uniform thickness

- Superior vibration transfer

- Higher compaction and consistent block height

Why Composite Manufacturing Works Better

- Zero water absorption

- Heat-resistant and UV-resistant

- No swelling or delamination

- High load-bearing capacity

- Long service life (10+ years in active production)

This is why engineered composites — especially those built using controlled formulations like PAC® technology — have become the top choice for modern Indian block plants.

Why the Manufacturing Method Dictates Performance

Different manufacturing processes → different outcomes:

Material Type | Manufacturing Strength | Weakness Origin |

Wooden | Simple, cost-effective | Natural variability, moisture absorption |

PVC | Smooth finish | Thermoplastic softening, low rigidity |

Recycled Plastic | Very low cost | Contaminated feedstock, inconsistent density |

Engineered Composite (PAC®) | Reinforced, calibrated, durable | Higher initial cost, but lowest lifecycle cost |

The difference becomes even more pronounced in India where:

- Summers reach 45–48°C

- Monsoon humidity is high

- Curing yards are outdoors

- Machines run high vibration cycles

- Handling conditions are rough

Materials built through controlled, engineered manufacturing simply perform better in these environments.

Where PAC® Pallets Fit Into This Landscape

Rajratan Industries pioneered PAC® technology to bridge the gap between durability, consistency, and real-world affordability.

Built from industrial-grade materials — not municipal waste — PAC® Pallets offer:

- Flatness engineered for block accuracy

- Stability under intense vibration

- Resistance to heat, UV, water, and deformation

- Long operational life (often 10+ years)

- A 40% buyback program supporting circular manufacturing

This combination of engineered materials + precision moulding creates one of the most reliable pallet solutions available to Indian block and paver manufacturers.

Conclusion: Quality Comes from Engineering, Not Appearance

Engineered composites PAC® Pallets from Rajratan — are designed to address all these limitations through controlled raw materials, structured manufacturing, and precision moulding.

When the manufacturing method is right, pallet boards stop being consumables — and become high-value, long-lived components of the production line.

- Phone: 0731 4045302

- Mobile: +91 96857 27927

- Email: info@rajratan.in