When it comes to logistics and warehousing, efficiency and safety are the top priorities. One factor that plays a significant role in achieving these goals is the capacity of your pallets. Specifically, plastic pallets have become the go-to choice for many logistics managers and businesses due to their durability, eco-friendliness, and design versatility. But how much weight can a plastic pallet support, and what factors influence its strength?

This guide will explore the types of weight capacities, key influencing factors, comparisons with other pallet types, industry standards, and real-world applications to give you a complete understanding of what to expect from plastic pallets.

Understanding Plastic Pallets and Weight Support

Plastic pallets are durable platforms made primarily from materials like high-density polyethylene (HDPE) or polypropylene (PP). They are widely known for their strength, resistance to environmental conditions, and reusability.

Knowing the precise weight a plastic pallet can support is vital in ensuring both safety and efficiency in your operations. Overloading your pallets might compromise their structural integrity, potentially leading to accidents or damage to goods. Several factors influence weight-bearing capacity—including design, material, and environmental conditions—which we’ll discuss in this blog.

Types of Weight Capacity in Plastic Pallets

Not all weight is created equal. The load a plastic pallet can handle depends on whether it is stationary, in motion, or held on a racking system. Here’s a breakdown of the three main types of weight capacity:

1. Static Load Capacity

Static load capacity refers to the amount of weight a pallet can support when it is stationary on a solid, flat surface. This could involve pallets stacked on top of each other for storage.

- Definition: The weight a pallet can support without moving.

- Typical Ranges: Plastic pallets can typically hold static loads ranging from 3,000 to 6,000 kilograms, depending on their material and design.

2. Dynamic Load Capacity

Dynamic load capacity measures the weight a pallet can safely hold when it is in motion, such as on a forklift or pallet jack. While moving, pallets face additional stresses that reduce their overall weight limit.

- Definition: The weight a pallet can support while being moved.

- Typical Ranges: Most plastic pallets can handle 1,000 to 2,000 kilograms dynamically.

3. Racking Load Capacity

Racking load capacity tells you the maximum weight a pallet can support when held on a racking system without bottom support. This type of capacity is crucial for warehouses that rely on vertical storage.

- Definition: The weight a pallet can support when stored on racks.

- Typical Ranges: Plastic pallets designed for racking generally support loads of 500 to 1,500 kilograms, depending on their structure.

Factors Affecting Plastic Pallet Weight Capacity

Several factors determine how much weight a plastic pallet can support. Understanding these can help you select the right pallet for your application.

1. Material and Design

- Material Type: Commonly used plastics include HDPE (high-density polyethylene) and PP (polypropylene). HDPE offers better impact resistance, while PP is preferred for applications requiring higher rigidity.

- Structural Design: Pallets with solid decks provide uniform strength, while open decks are lightweight and improve ventilation, but might have less capacity.

2. Environmental Conditions

- Temperature Extremes: Heat can make plastic pallets more pliable, while cold can make them brittle. Always check the specifications if your operations involve temperature-controlled environments.

- Chemical Exposure: Certain chemicals can weaken plastic over time. Ensure compatibility before exposing pallets to such conditions.

3. Load Distribution

- Even Weight Distribution: Pallets perform best with evenly distributed loads. Uneven loads or point loads can create stress concentrations, reducing the overall weight the pallet can support.

Plastic Pallets vs. Other Pallets

When weighing your options between plastic, wooden, and metal pallets, it’s important to understand how they compare in strength and usability.

Plastic vs. Wooden Pallets

- Plastic Advantages: Reusable, resistant to moisture and pests, lightweight, and long-lasting.

- Wooden Advantages: Initially cheaper and great for one-way shipping.

- Weight Capacity: Plastic pallets often surpass wood in dynamic and racking capacities.

Plastic vs. Metal Pallets

- Plastic Advantages: Lighter, less expensive, and rust-resistant.

- Metal Advantages: Unmatched durability and extremely high weight capacity.

- Weight Capacity: Metal pallets edge out plastic in handling extreme loads but at the cost of added weight and less eco-friendliness.

Overall Comparison

While wooden and metal pallets have their benefits, plastic pallets strike the best balance between strength, reusability, and eco-friendliness, making them a preferred option for many industries.

Industry Standards and Testing

Before a plastic pallet hits the market, it must go through rigorous testing to ensure reliability. Here are the relevant standards and methods:

- Standards: Look for pallets tested against ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials) standards.

- Testing Methods: Pallets are subjected to compression tests, impact tests, and environmental conditions to determine their capacities.

- Certifications: Always choose pallets with certifications from reliable testing bodies, as these confirm the safety and reliability of the product.

Real-World Applications of Plastic Pallets

Plastic pallets are a staple in industries like retail, pharmaceuticals, agriculture, and manufacturing.

- Retail: Lightweight designs and high static load capacity make plastic pallets ideal for moving bulk stock.

- Pharmaceuticals: The hygienic nature of HDPE/PP pallets ensures compliance with safety standards.

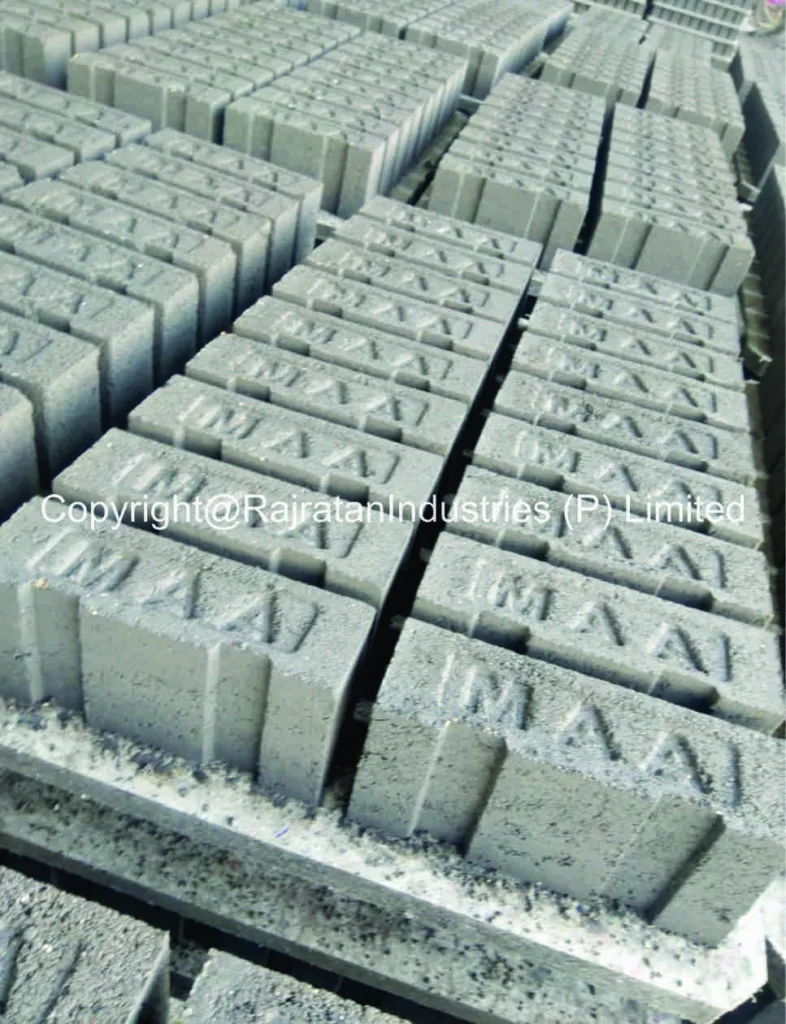

- Agriculture & Construction: Tools like the PAC Pallets designed by Rajratan Industries are specifically built to handle the heavy loads of bricks, blocks, and pavers.

A Case Study in PAC Pallets

Rajratan Industries, a leader in the manufacturing of PAC Pallets, has helped countless businesses improve their operations by offering durable, eco-friendly solutions for bulk material handling. With high load capacities tailored for specific client needs, PAC Pallets showcase the best of modern plastic pallet technology.

Want to learn how PAC Pallets can revolutionize your business? Get a free sample PAC Pallet today! Call us on +91 9685927927 (Monday to Saturday, 10 AM to 6 PM).

Future Trends in Plastic Pallets

Advancements in plastic technology and increasing demand for sustainability mean that plastic pallets are only going to get better. Expect innovations such as biodegradable plastics, IoT-enabled tracking chips, and even greater load capacities in the years ahead.

Choose the Right Pallets for Your Needs

Plastic pallets offer an unbeatable combination of versatility, strength, and sustainability. However, choosing the right one for your business depends on understanding its weight capacity and operational requirements. Whether it’s for retail, warehousing, or heavy-duty industries like construction, plastic pallets—especially PAC Pallets from Rajratan Industries—are up to the task.

Need help finding the perfect plastic pallet? Request your free PAC Pallet sample today! Call +91 9685927927 (Monday to Saturday, 10 AM to 6 PM) and experience the difference.